Fleet management cost analysis is the most effective way to make data-driven decisions to maximize profitability. Using software makes it easy to track expenses and centralize your data.

Understanding Fleet Management Cost Analysis

Controlling a budget is one of the most meticulous tasks a fleet manager faces, but proper expense tracking enables in-depth fleet management cost analysis. Maintaining an organized record of purchases allows managers to gather insight that can affect their profitability, return on investments (ROI) and every aspect of their fleet management strategy.

Many fleet managers struggle with their budgets due to a lack of real-time visibility. Manually tracking expenses and crunching numbers isn’t just a poor use of your time—it also can result in inaccuracies and a lack of clarity into your present budget.

Fleet management software allows managers to track expenses in real time and calculate the total cost of ownership (TCO). With an accurate view of fleet expenses, you can effectively analyze expenses on a granular level, forecast expected costs for individual assets and make decisions to improve operations and increase profitability.

Jump to a section to begin learning:

- Calculating Total Cost of Ownership

- Leveraging TCO to Make Data-Driven Decisions

- Why Fleetio is the Best Tool for Cost Analysis

What Goes Into Calculating Total Cost of Ownership?

The first step towards effective fleet management cost analysis is understanding your fleet’s total cost of ownership (TCO). Determining your fleet’s TCO may seem intimidating, especially if you’re still using outdated systems, but calculating TCO doesn’t have to be difficult.

Tracking operating expenses for each vehicle in fleet management software enables you to access real-time operating costs to determine total spend. Because your TCO is constantly fluctuating, having a tool to monitor costs and routinely generate expense reports is the best way to stay informed.

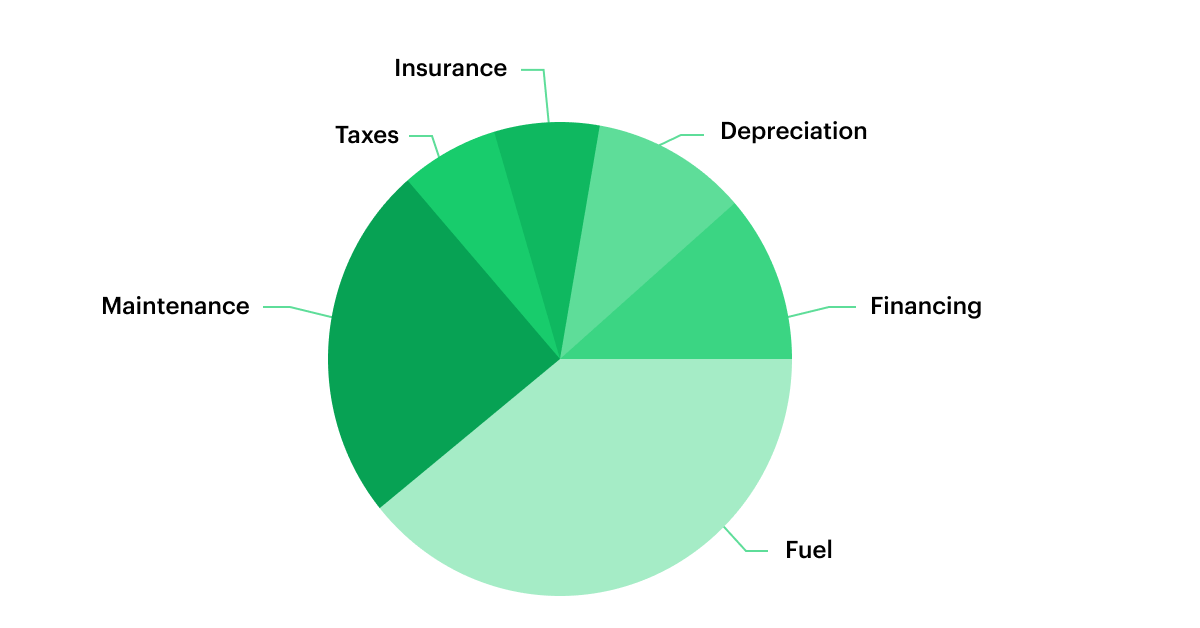

To effectively track and analyze your TCO, you must understand exactly what is included in it. Breaking down expenses into categories allows you to clearly understand how each aspect of your fleet impacts your bottom line.

Fixed Vs. Operating Costs

Fleet expenses are divided into fixed and variable costs. Fixed costs, by nature, are established costs that don’t change regardless of usage. Some examples of fixed costs include:

- Taxes

- Insurance

- Depreciation

- Licenses and permits

- Loans and lease payments

Operating costs, on the other hand, are variable and can fluctuate depending on a variety of factors. Controlling variable costs is essential in maximizing profitability. Your two largest variable costs are maintenance and expenses. Other variable costs include:

- Part replacement

- Tolls

- Parking

- Detailing

As you can imagine, some variable costs can fluctuate greatly month-to-month, while other variable costs, like parking fees, are incidental in nature. No matter the expense, every dollar counts towards your bottom line.

Fleet management cost analysis enables you to dive into variable costs and determine ways to reduce them. Is there a particular vehicle eating away at your maintenance budget? Are you spending too much on fuel? Monitoring this data and asking questions helps you reflect on your decisions as a fleet manager and make strides towards efficiencies across operations.

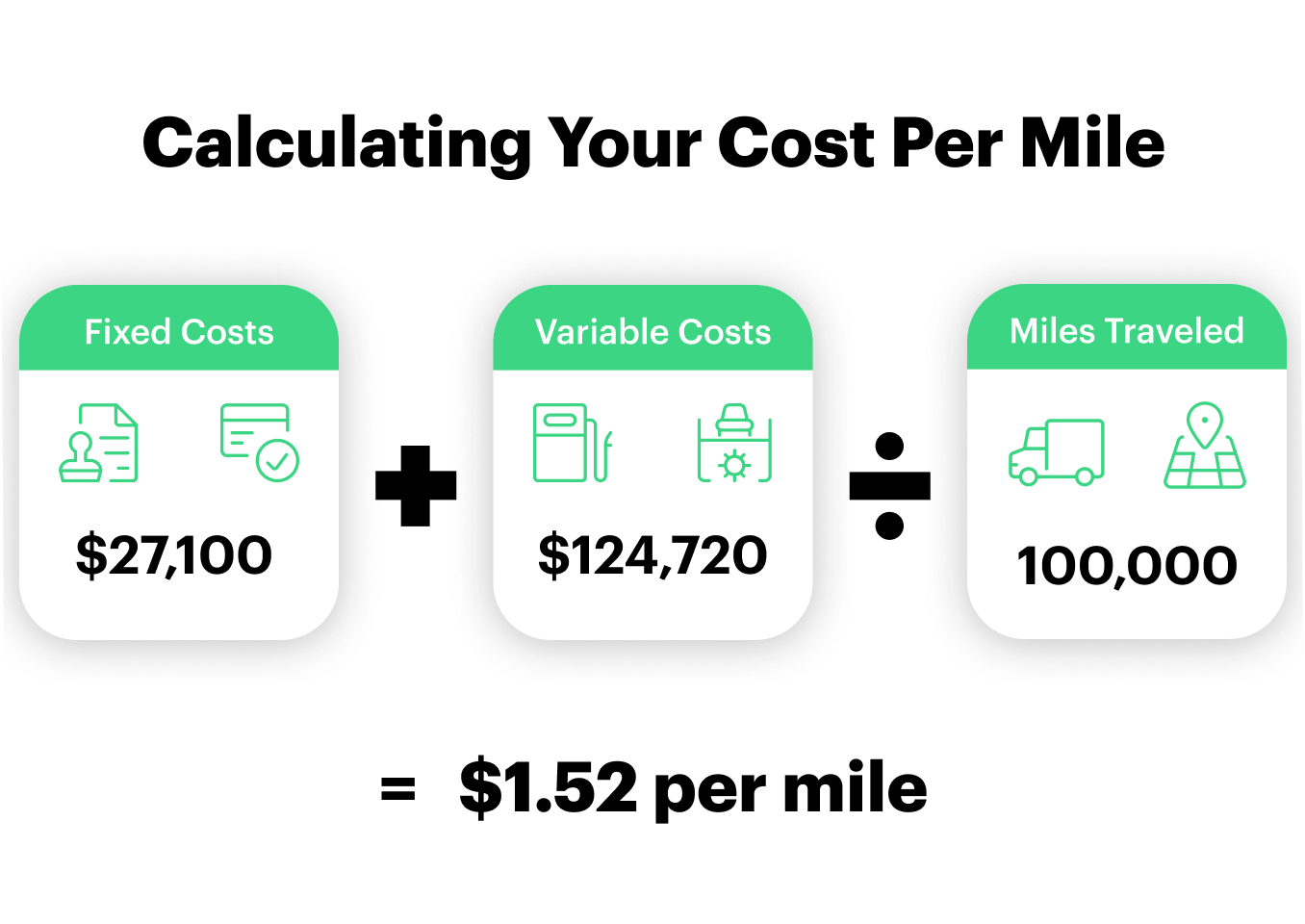

Calculating Cost-Per-Mile

Once you have an accurate view of your annual TCO, you can confidently determine your cost-per-mile. This number is calculated by taking your TCO and dividing it by miles driven in a year. You can also calculate cost-per-mile by month.

To make this process easier, fleets can integrate their GPS or telematics systems with fleet management software to automatically sync odometers. By automating both expense management and odometer tracking, fleet managers can accurately determine their real time cost-per-mile in seconds.

Leveraging TCO to Make Data-Driven Decisions

Fleet management software makes it easy to determine your TCO, but once you’ve got it calculated, what’s next?

Having a complete breakdown of your TCO empowers you to fully optimize your fleet management strategy. Managers can set baseline metrics for similar vehicles and forecast expected costs for each vehicle’s lifespan.

Managers can also create configurable reports and share them with stakeholders to develop strategies to improve operations. From maintenance decisions to how you acquire and dispose of vehicles, fleet management cost analysis can positively impact every aspect of your business.

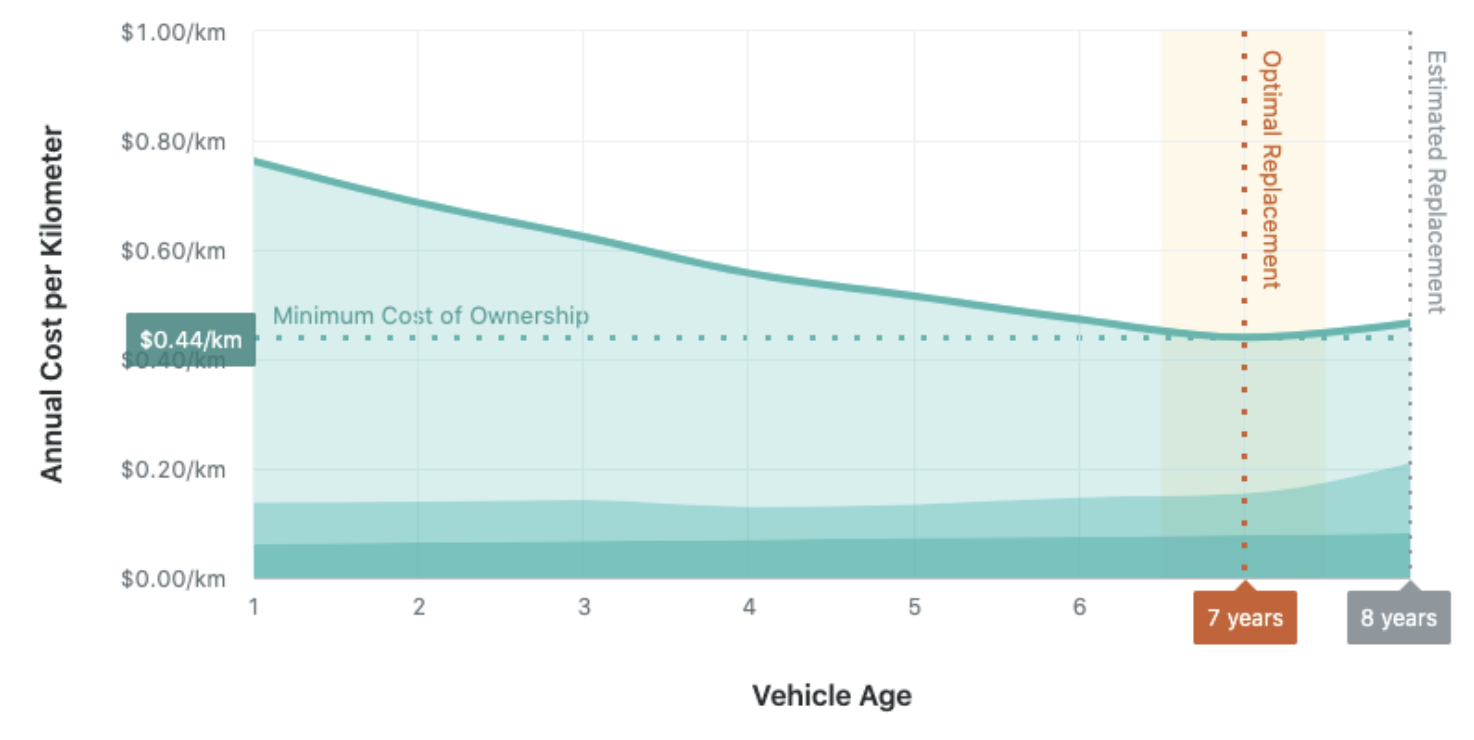

Vehicle Replacement

It’s best to face challenges head-on, so it’s important to develop a clear vehicle replacement strategy. While this task can be daunting if you don’t have a comprehensive view of expenses, centralizing your fleet’s data in software makes it easy to analyze service history and expenses by vehicle.

Communicating value to your stakeholders regarding new vehicles is easier when you have hard data on your side. Creating configurable reports in fleet management software allows you to present historical and current data to leadership and illustrate how new vehicles can positively impact your TCO.

Managers can generate configurable reports regarding utilization, operating costs, depreciation, salvage value and other data points that help estimate a vehicle’s optimal replacement window. For example, fleet managers in the trucking and logistics industry could leverage reports from truck management software to go into a conversation about vehicle replacement with clear data and make the best financial decisions for their fleet.

Maintenance Strategy

As we mentioned earlier, maintenance is one of your largest variable costs. Developing strategies to decrease your maintenance expenses is one of the best ways to improve your bottom line.

Taking a proactive approach to maintenance by following your OEM’s recommended maintenance plan ensures you’re keeping your vehicles in good operating condition. Creating service reminders in software notifies you of upcoming service tasks, helping you keep up with routine maintenance tasks.

Proactively managing maintenance tasks, both routine and unplanned, helps avoid costly downtime and extend your vehicle’s lifespan. By taking care of problems quickly, you can avoid issues compounding and resulting in hefty repair costs and strengthen a fleet compliance plan to improve vehicle safety for your operators.

Buy vs. Lease vs. Rent

Leveraging TCO data can help you determine whether to lease, buy or rent your fleet. Before making the decision, consider your current budget, turnover rate and repair costs.

Renting certainly has its benefits in terms of preserving capital and improving utilization rates. That said, if your fleet is constantly on the road, it’s important to consider mileage limitations and wear-and-tear fees.

Similar to renting, leasing can help you preserve capital and have access to newer vehicles. One of the drawbacks to leasing is that it can potentially be more expensive in the long-run due to hidden fees. With renting and leasing, you also don’t receive tax depreciation benefits.

Purchasing vehicles outright allows you complete control over your fleet. This can be helpful, especially if your fleet has a low turnover rate, yet incurs a lot of wear-and-tear. That said, purchasing vehicles requires a lot of capital and a lot of responsibility that lasts beyond the initial purchase. When it comes to maintenance, acquisition and disposal, the buck stops with you.

4 Reasons Fleetio is the Best Option for Fleet Management Cost Analysis

When it comes to fleet management cost analysis, you need software that eliminates data entry and provides complete visibility into operations and expenses. That’s where Fleetio comes in.

Fleetio centralizes all of your fleet data into an easy-to-use software and mobile app. Managers can manage day-to-day operations, like maintenance and assignments, while also monitoring utilization, performance and expenses. Here are four Fleetio features you can leverage to fine-tune your fleet’s budget.

1. Automating TCO Calculations

Fleetio’s robust reporting capabilities make it easy for you to view your TCO at a high level or in granular detail. Instead of combing through spreadsheets and crunching numbers, you can let the software do the work for you.

Reports are automatically generated from data entered via mobile app or integrations. All maintenance and fuel expenses are aggregated into the software, allowing you to generate configurable reports to share with stakeholders. By taking the guesswork out of TCO, you can confidently make decisions regarding the future of your fleet based on accurate, real-time expense data.

2. Optimal Replacement Analysis

When it comes to vehicle replacement, Fleetio’s free Vehicle Replacement Calculator allows you to take a data-driven approach. Fleet managers can forecast replacement based on a variety of factors including utilization, operating expenses and depreciation.

Managers can see how estimated replacement dates change based on different variables. The ability to apply assumptions and monitor progress allows you to get an in-depth look at the vehicle life cycle and determine strategies to lengthen asset lifespan.

3. Maintenance Shop Integration

For fleets who outsource their maintenance, having complete control over repairs is the best way to control expenses. Unfortunately, managers can have difficulty with price transparency from shops or fleet management companies (FMCs).

Fleetio’s Maintenance Shop Integration allows managers to approve or reject service instantly via web or mobile app. Managers can review repair orders to determine the right repairs are being performed and the right parts are being used.

Instead of playing phone tag with the shop or seeing surprise line items on your invoice, you know exactly what you’re paying for and can take steps to control your maintenance costs.

4. Fuel Tracking

With the median annual cost of fuel for an asset coming in at approximately $5,740*, tracking fuel costs and consumption is essential to controlling your TCO.

Fleetio simplifies fuel data collection to reduce manual fuel entry. Instead of fleet managers drowning in fuel receipts, drivers can log receipts on-the-go in their mobile app or fleets can integrate their fuel cards to automatically pull transactions into a fuel management software.

Tracking fuel over time provides insight into fuel economy and helps managers develop strategies to reduce fuel spend. Whether that’s optimizing asset utilization and routes or looking into alternative fuels, Fleetio gives you all the data you need to make informed decisions.

See How Fleetio Can Help You Optimize Cost Analysis

Fleetio is a cost-effective solution with an outstanding return on investment (ROI). By providing data transparency, Fleetio empowers managers to use fleet data to their advantage. Instead of spending hours on data entry and hunting down information in spreadsheets, you can access the data you need in an instant.

*This amount is based on data from over 46,500 assets

Analyzing expense data is the key to your fleet’s success! Start your free trial of Fleetio or request a demo today.