It’s difficult to create a fleet maintenance process. But once you’ve done that, the next hurdle is determining how to monitor it effectively and get your team on board.

We discussed these topics with Josh Adam, fleet maintenance consultant and founder of inta maintenance, in our webinar Simplifying Fleet Maintenance for SMBs.

Let’s dive in.

But first, if you haven’t already, make sure you check out our previous blog post outlining six steps to creating an effective fleet maintenance process.

Monitor metrics and visualize

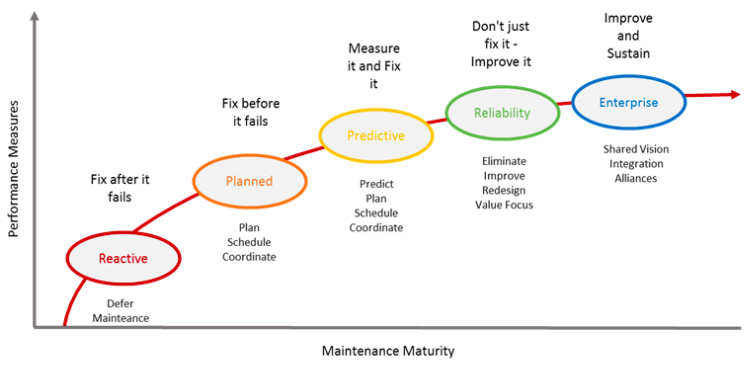

It is a good practice to build a standard set of metrics you regularly track for your fleet. The best metrics to monitor may vary depending on where you fall on the Maintenance Management Maturity Curve.

Metrics to track include:

- Performance Metrics

- Backlog Volume

- Schedule Compliance

- Breakdown Percentage

- Process Metrics

- Percent of Issues Approved

- Schedule Loading

- Work Order Completion Quality

No matter which metrics you choose to track, make sure everyone can see them, understand what the data is telling them and know what they can do to impact the numbers.

From his experience as a maintenance consultant, Josh Adam found that:

-

Monitoring trends rather than a single number at given point in time tells a better story

-

Establishing targets or limits to stay within create better buy in

-

Using Red, Amber and Green colors as indicators of success makes it really simple for everyone to understand what the data is telling them

-

Celebrate the “Reds” because they are your biggest opportunity to improve and do something about turning it Green

Let your people in

Achieving excellence in maintenance means getting all of these activities right—the fleet maintenance software, process and people. Too often companies get two out of three working well.

If you are going to invest in implementing a fleet maintenance software and process, it is in your best interest to also make it accessible to your people.

It is easy to build out the maintenance process yourself and lose your people in the noise. But they are most crucial part of this process because they are the ones who have to execute on it!

So, remove any non-vital steps from the process to make it as reasonable as possible for your people. Also, make sure you invest time bringing your people up to speed with why this is important, how to use the fleet maintenance software and process and who does what and when.

The “who does what and when” piece is one of the biggest engagement levers you can pull. Let your people discuss and determine who is best to:

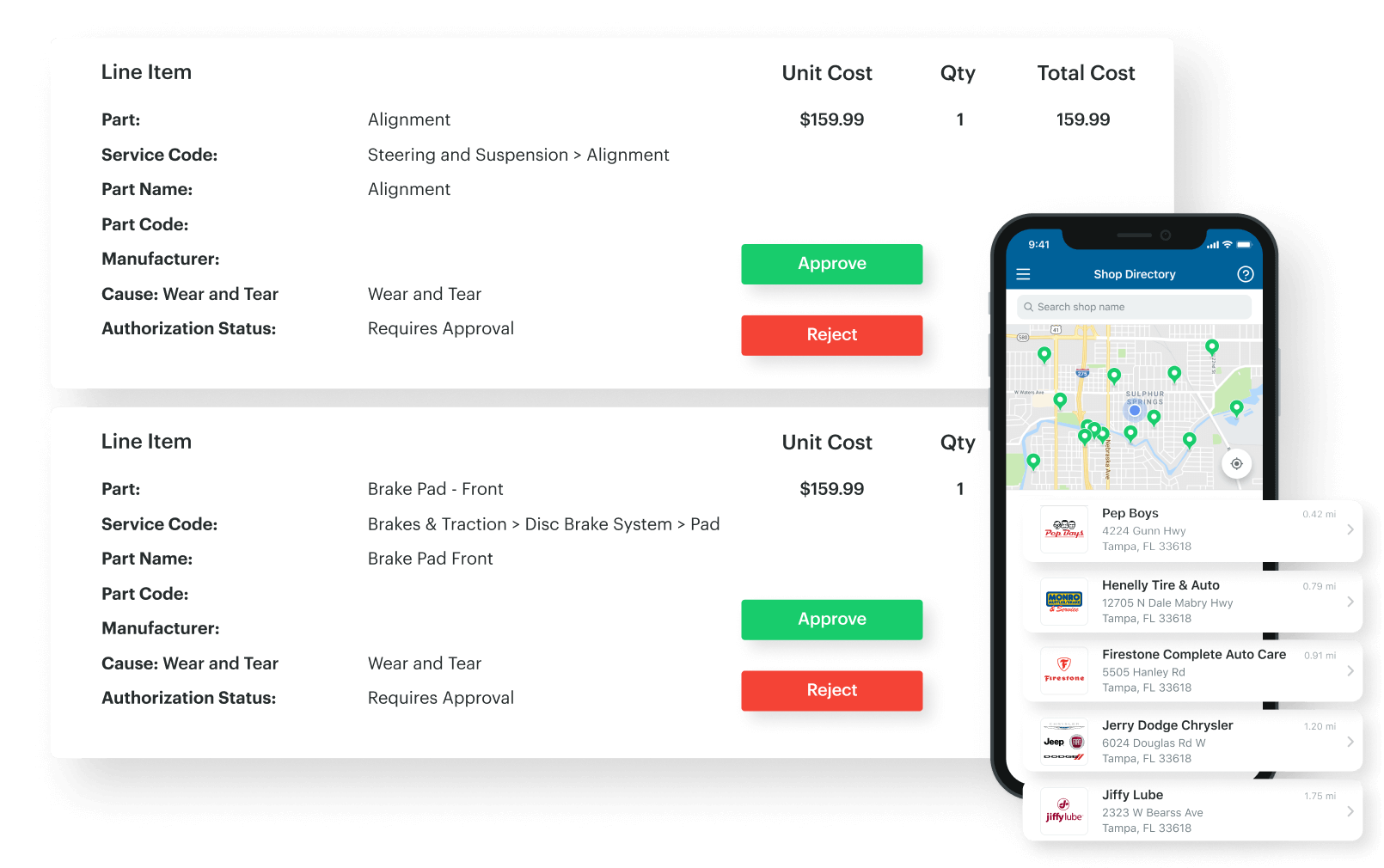

- Review and approve or reject new issues and what time of the day to do it

- Determine in-house or outsource for each task

- Develop scheduling guidelines

- Determine which metrics are displayed and how

Then of course, don’t forget to recognize and reward your team in a timely fashion.

What gets measured gets managed and what gets rewarded gets repeated.

Being a contagious maintenance leader, involving people in your vision, helping your people understand the foundation of your asset management and being open to feedback will encourage excellence in your team. Positive reinforcement can go a long way and build loyalty for you and the maintenance process.

You can fully automate the maintenance process with our fleet maintenance software and new Outsourced Maintenance Automation. Get discounts on service at our network of shops, consolidate billing to get one invoice from all vendors and avoid manual data entry all together.