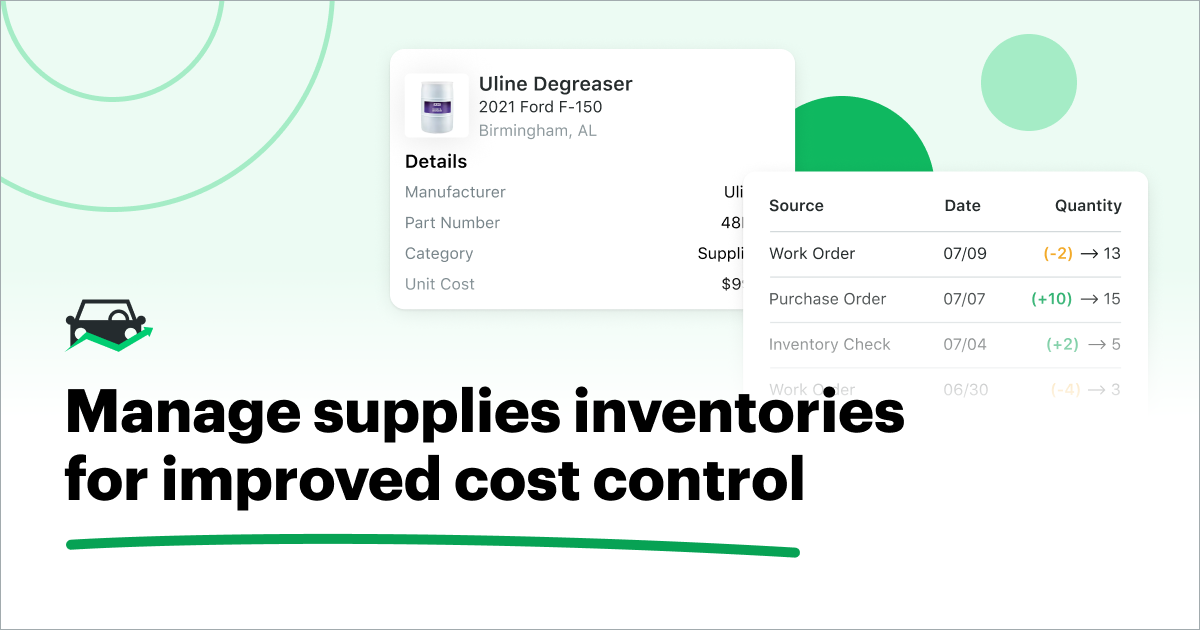

Fleets are feeling the effects of inflation and supply shortages, especially when it comes to procuring trade supplies and keeping them properly stocked. With fleet management systems, fleets can track and manage industry-specific supplies and materials like chemicals, detergents, fiber optics cables, etc., allowing managers to optimize on-hand counts, account for discrepancies and better control related spend.

Challenges in Procuring Needed Supplies

Fleets have had to contend with a lot over the past few years: increased lead time for asset procurement, difficulty getting replacement parts, ongoing labor shortages and rising fuel prices. Continuing supply chain issues combined with record-high inflation has also made trade supplies and material procurement more difficult and costly. "The shortages impact materials, such as steel, aluminum, copper and plastics, whose costs are expected to rise in coming months. Among metals, the price hikes could be 20 to 30 [percent], while prices of plastics could almost triple," according to Larry Anderson, Editor for HVACInformed.com. "Copper futures recently reached an all-time high, and steel price indexes are also at record levels."

Both agricultural and pest management fleets are finding the need to switch to more affordable — and sometimes less effective — insecticide brands and reevaluate current processes to ensure that, should their supplies not reach them when needed, they have a backup plan. Across the United States, utility companies are experiencing wait time increases of five to six months for transformers and fiber optics cables. In the current economic climate, it seems no industry has gone untouched. One way to combat these challenges is to get a better understanding of when and how your supplies are being used and number/quantity used per job (or per time period) to surface discrepancies in use and quality and hone in on unnecessary waste.

Benefits of Using a Parts Inventory System to Track Supplies

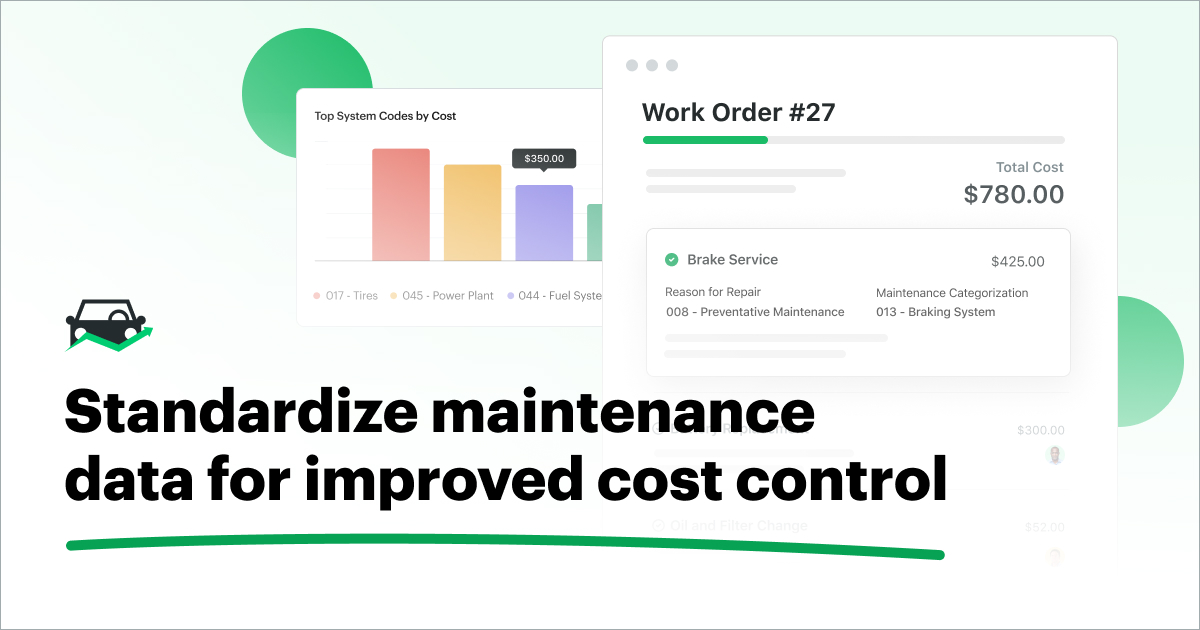

Automated fleet management software (FMS) is aimed at helping improve and simplify fleet asset management. Trade supplies and materials used by drivers over the course of daily operations are just as important to track. While you can use a robust parts inventory spreadsheet to track supply counts and usage, using an FMS’s fleet parts inventory management feature offers enhanced insights through automated reporting, including:

Purchase orders

Purchase order reports provide detailed information around supply and material purchases, including order status, description, labels, location, vendor, who created the order and when, who approved the order and when, total order quantity and a detailed breakdown of cost, including shipping, discounts, taxes and total cost. When adding parts and supplies to your inventory list, you can create custom labels — either by broadly labeling them as supplies or materials or being more specific by labeling the product type, such as industrial cleaning solutions. Reports are filterable, allowing you to easily sort orders by label, vendor and even manufacturer. You can use purchase order reports to track and monitor quantitative data around number/volume of product used over a specific period, cost of product procurement over time and more.

Parts by location

Fleets with multiple locations (or depots) can track and monitor supply orders and usage histories by location with parts by location reports. This report shows current on-hand counts and reorder thresholds for every location that stocks it, as well as any current orders they may have. Fleets can use the data from this report to see if any locations have a surplus of stock that understocked locations can pull from, as well as discrepancies in supply quantities used across locations with similar demand-for-use (usage histories plus customer/job volume). Monitoring this data can help reduce unnecessary spend.

Parts activity

Parts activity reports offer a wealth of useful information, especially for fleets looking to switch product brands to reduce cost. Testing the efficacy and value of different product brands can help you determine if switching is really as cost effective as the sticker price suggests, or if an increase in product quantity needed as a result of the switch is offsetting upfront costs. To determine product value, you can compare different brands’ historical usage rate and total cost data over a specific period. Even if you’re not contemplating a product switch, parts activity reports can help you surface costly discrepancies in product use, including misuse and theft. Simply compare customer/job volume with product usage rates over a specified period, and if usage rate abnormally exceeds customer/job volume, there could be a problem.

Optimize supplies inventories and achieve better cost control with Fleetio

Start your free trialWhen adding supplies to your parts and inventory list in FMS, be sure to include clearly defined, standardized labels and categories to allow for precision reporting so you can quickly and easily surface the data you need.

Want supplies and materials inventory data on a more granular level? You can use customizable digital inspections in FMS to track key data such as: part number (or other identifying criteria), starting quantity, job quantity, job details (job code, invoice number, client name or other identifying criteria), product issues, and who used the product and when. This data can help fleets improve usage accountability and determine any discrepancies as well as their source. By managing supplies and materials inventories in FMS, whether just using the parts inventory feature or combining it with customized inspections, fleets can gain insights into usage and value for improved cost control.

Want to see how Fleetio can help you improve supply inventory management, increase accountability and reduce unnecessary supply spend? Start your free trial or request a personalized demo today!