Building products distributor relies on Fleetio to stay compliant and effectively manage its dispersed fleet assets.

Company Objectives:

- Ensure safety and compliance through inspections

- Increase efficiencies and reduce expenses

- Take a proactive approach to maintenance

Inspecting the Unexpected

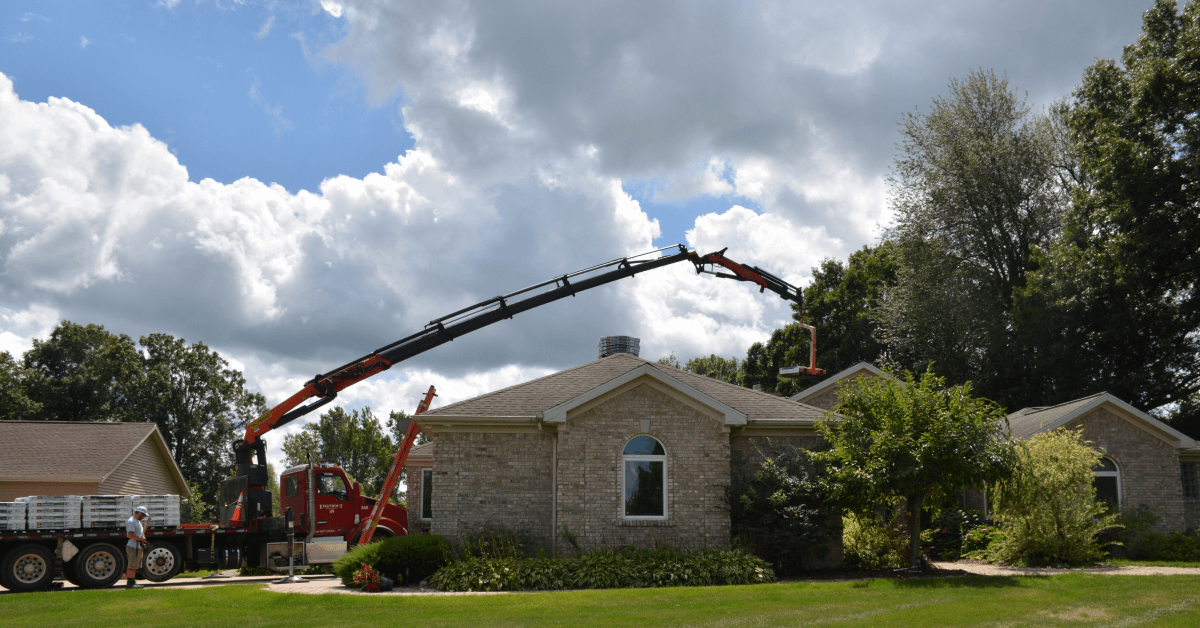

Since 1894, Eikenhout Inc. has supplied the state of Michigan with exterior building products for residential and commercial construction. The company relies on its mobile assets to deliver exceptional service customers have come to expect.

The company’s fleet consists of a variety of assets, from trucks and trailers to specialized equipment like crane trucks, Moffett mounted forklifts and SkyTraks. To manage its nine locations across the state of Michigan while maintaining its high standard of customer service, the company needed fleet management software with a robust set of capabilities.

Eikenhout quickly realized the benefits and scalability a fleet management solution like Fleetio could provide to its diverse fleet. The company initially used Fleetio to manage its vehicles, but swiftly added 45 forklifts to the system to ensure visibility across all asset types.

In the last four years using Fleetio, Eikenhout has added additional assets as its fleet has grown to over 160 assets, eliminating its reliance on inefficient and antiquated solutions like spreadsheets.

“To go from spreadsheets to Fleetio, in terms of horsepower, is no comparison. It’s a pedal bike versus a Mustang GT 5.0.”

- Curt Van Heuvelen, Eikenhout Safety and Training Coordinator

Fleetio provides essential features like configurable preventive maintenance schedules, the ability to track maintenance and expense insight and an intuitive mobile application, Fleetio Go, to manage fleet inspections from anywhere. One of Eikenhout’s favorite features of Fleetio Go is configurable Driver Vehicle Inspection Report (DVIR) forms.

These digital forms can be configured to cover any detail of inspections and help the fleet maintain DOT compliance. A custom version is used to promote jobsite safety by requiring drivers to make sure it is safe to bring a piece of equipment into the property.

Drivers can conduct inspections from their smartphone and immediately pass or fail an item based on safety criteria at a given jobsite. If there’s a failure, the branch managers are notified immediately through Fleetio.

“Fleetio is a very easy system to access and helps make sure we are compliant with government regulations. Non-compliance is not an option for us. There’s a reason we’ve been in business for so many years, and cutting corners isn’t (it).”

- Curt Van Heuvelen, Eikenhout Safety and Training Coordinator

Uncovering Unnecessary Expenses

Prior to Fleetio, any cost analysis was done through a spreadsheet and relied on the accuracy of the information entered and calculated. It was an inefficient process that simply wasn’t effective for Eikenhout’s operations.

Ownership is responsible for monitoring and replacing trucks as well as analyzing costs related to fuel and maintenance services. Due to this, the company needed a way to create and share reports with necessary stakeholders that they could securely access anywhere.

When there’s an issue specifically related to expenses, the company is able to quickly respond accordingly to mitigate any potential impact. A great example of this is through cost comparison for similar model vehicles in the fleet.

By comparing miles per gallon and total cost per mile with similar model trucks at different branches, Eikenhout can easily identify any discrepancies. The results can lead to addressing problems such as driver behavior or higher than normal service costs for certain trucks or locations.

“Since we’ve gone to Fleetio, it’s really streamlined the process and with just a few clicks we can get a lifetime cost for different assets within our fleet. We can identify which truck, trailer or piece of equipment is costing us too much money. It’s made the process much more scientific.”

- Curt Van Heuvelen, Eikenhout Safety and Training Coordinator

Taking a Proactive Maintenance Approach

With such a dispersed fleet, Eikenhout needed maintenance software to initiate repairs and service at optimal times while managing the entire maintenance process in a single platform.

Fleetio not only offers much-needed visibility into the status of each asset, but essential insights and alerts help the company optimize its maintenance process and minimize downtime.

“The DVIR features along with the ability to track service and integrations with fuel cards have made Fleetio a phenomenal contributor to our company’s success.”

- Curt Van Heuvelen, Eikenhout Safety and Training Coordinator

Eikenhout’s fleet puts on a lot of miles with city driving, which can expedite the need for certain maintenance. In the past, the company would often conduct maintenance reactively. Using Fleetio’s configurable service reminders, administrators are now automatically notified when service is approaching.

This has helped streamline the company’s proactive approach to maintenance management. Branches can identify when a vehicle or piece of equipment will be in service ahead of time and make necessary arrangements to avoid disruptions to onsite job tasks.

“The system (Fleetio) automatically generates service reminders based on a time or mileage schedule so the manager or dispatcher knows it’s coming and can schedule that particular asset to be out of service on a particular day.”

- Curt Van Heuvelen, Eikenhout Safety and Training Coordinator