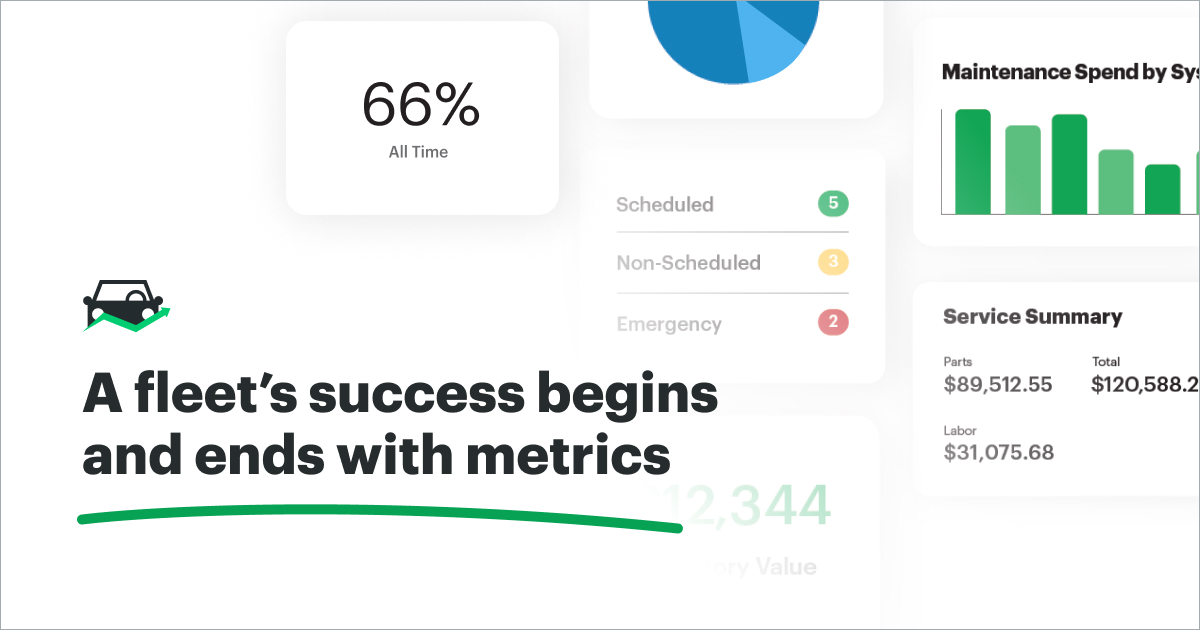

Making the best decisions for your fleet operations begins and ends with tracking fleet metrics. Having a central location for all fleet metrics gives you a comprehensive view of your assets to ensure success.

Analyzing Fleet Metrics

As a fleet manager, you have a lot of data at your fingertips regarding your drivers and assets. How you leverage that data ultimately determines the success of your fleet, but determining which data to track closely can be a challenge. To help you prioritize, we’ve compiled fifteen of the most important fleet metrics you should be tracking.

If you’re just getting started with fleet data, we created a free Fleet Management Spreadsheet template to help you keep tabs on key fleet metrics.

Maintenance Metrics

1. Inspection Results

Driver Vehicle Inspection Reports (DVIR) keep fleets compliant and alert managers of vehicle issues, but they are also a key to understanding the health of your assets.

Leveraging DVIR data grouped by user or vehicle provides insights by ensuring you don’t miss common defects across your fleet.

With fleet management software, you can view failure summaries and surface your most common inspection failures. Seeing patterns of issues across your fleet can help you improve preventive maintenance strategies and decrease downtime.

You can also create custom reports, like one for DVIR failures that need immediate attention, so managers can track the progress of critical issues and analyze all failures in a central location.

2. Preventive Maintenance Practices

Preventive maintenance (PM) is one of the best ways to lengthen the lifespan of your assets and save on costly repairs. Implementing a PM schedule allows you to track and analyze all routine maintenance.

Fleet maintenance software gives both high-level and granular views of open work orders and service tasks. View the status of PM tasks on every asset and ensure maintenance is being completed on time.

While PM can greatly improve your fleet, all potential benefits are lost if you get off schedule. Aiming for a 95 percent on-time success rate for PM ensures fleet uptime.

3. Diagnostic Trouble Codes

Pairing a telematics device with your fleet management software allows you to receive diagnostic trouble codes (DTC) from your assets in real-time.

Being alerted to issues immediately allows you to start the maintenance process quickly, but it’s important to keep a running list of faults.

A faults summary page in your fleet management software allows you to see the most common faults across your fleet and view a list of vehicles with the most fault occurrences.

Monitoring these faults can help you better plan maintenance for your assets, as well as alert you to vehicles with recurring issues to determine replacement strategies.

4. Repair Turnover

Preventing downtime is always front of mind for fleet managers, so when vehicles are parked in the shop for a number of days, you’re rightly concerned.

Whether you perform maintenance in-house or outsource to a third party, monitoring the time vehicles are spent in the shop ensures repairs are being completed on time.

In fleet management software, you can view service reports to monitor the start and completion dates and see status updates on maintenance to ensure the productivity of the maintenance team.

5. Odometer Readings

The odometer is the key to unlocking tons of fleet insight. From preventive maintenance scheduling to determining vehicle replacement, tracking odometer readings ensures you stay prepared and proactive.

As most PM tasks are based on mileage and hour intervals, receiving regular odometer updates allows you to keep your vehicles in top condition. You can also use odometer readings to manage drivers and lower fuel costs.

To ensure accurate reporting, consider integrating a telematics device that will automatically update numbers in your fleet management software. Telematics data eliminates the risk of manual errors in odometer reporting and provides complete visibility into your fleet.

Cost Metrics

6. Fuel Management

Fuel is one of the largest ongoing fleet expenses, so it’s crucial to closely track usage and spend. Having a system to monitor and calculate fuel costs and consumption in real-time can benefit your fuel management process.

A fuel management system helps you know the ins and out of your fuel economy by automatically determining cost-per-mile to forecast future expenses. Viewing costs in real-time helps optimize financial allocation.

Manually tracking fuel consumption is a poor use of time, and receipts are often lost by drivers. With fleet management software, drivers can easily log fuel entries into a mobile app to eliminate hours of data entry.

To further streamline the fuel management process, consider integrating fuel cards with fleet management software to automatically download fuel transactions and avoid invalid readings.

7. Total Cost of Ownership

Perhaps the most important and comprehensive metric you should be tracking is your fleet’s true total cost of ownership.

This is one of the most challenging aspects to track and manage, but knowing your fleet’s TCO allows you to confidently make data-driven decisions about your business.

Fleet management software calculates TCO from an aggregate of your fleet’s data. Getting a break down of your fleet expenses gives you an understanding of your return on investment (ROI). It also helps determine strategies for preventive maintenance, vehicle replacement and whether to purchase or lease future vehicles.

8. Asset Utilization

Investing in a fleet isn’t cheap, so getting the most out of your assets is essential. Monitoring your fleet assets will help increase your ROI and maximize their lifespan.

Tracking average hours of use or miles per day not only keeps you on time with preventive maintenance scheduling; it also helps you maintain a sustainable fleet size.

After monitoring asset utilization for several months, you may discover under-utilized vehicles in your fleet that can be better used or sold for a profit. On the other hand, you may discover your current fleet size can’t meet demand.

Proper asset utilization levels vary, but finding your fleet’s sweet spot can help you avoid costly expenses or unplanned downtime.

9. Vehicle Replacement

Without a doubt, vehicle replacement is one of a fleet manager’s most daunting tasks. That being said, if approached strategically, vehicle replacement can be mostly painless.

Sometimes, vehicles stay in operation longer than they should, causing asset performance to decline while operating costs rise. Though replacing assets is expensive, having aging vehicles constantly in and out of the shop will negatively affect your bottom line.

Tracking fleet metrics like odometer readings, service history and TCO can help decide whether a vehicle should be replaced. Leveraging fleet management software ensures you make the right decisions at the right time.

10. Parts and Inventory

If you’re managing maintenance in-house, you need to have the right tools on hand to minimize vehicle downtime. Tracking your parts inventory helps avoid stockouts and reduces unnecessary inventory costs.

Because parts make up over one-third of vehicle maintenance costs, controlling inventory levels is crucial to your fleet management system. Keeping track of part quantities in an online parts database provides insight into part usage.

Regularly viewing part order history and tracking inventory values helps you make actionable decisions on future spending and efficiently manage inventory storage.

Driver and Asset Metrics

11. GPS and Telematics

Telematics data provides valuable fleet visibility and insight into asset health. Integrating your telematics device into fleet management software increases the value of your data.

While tracking meter readings can help improve PM, telematics data helps you proactively monitor driver behavior and identify unsafe practices that can harm the driver and vehicle.

Telematics data also enables you to take a deeper dive under the hoods of your assets. Keep track of the frequency of diagnostic trouble codes (DTC) or engine fault alerts to quickly manage maintenance and observe trends across your fleet.

12. Accidents and Safety

Safety is a critical aspect of any fleet and should be tracked just as closely as maintenance and repairs. Taking a proactive stance on fleet safety ensures the well-being of your drivers and assets, and decreases unnecessary expenses.

Implementing safety procedures into your driver management system can help your fleet maintain airtight compliance. Tracking fleet metrics like driver behavior and DVIR results decrease liability and help avoid costly fines and accidents.

Fleet management software will also alert you to vehicle recalls. Closely monitoring these potential issues can help you take action quickly.

13. Driver Assignments

While fleet managers focus heavily on their assets, it’s also important to track and manage your drivers. A driver management system ensures the safety and productivity of your drivers and gives you peace of mind that your assets are in safe hands.

Fleet management software provides several ways and integrations to track drivers and their behavior. Assigning vehicles to drivers allows you to quickly view the duration and distance of assignments and keep your drivers accountable.

Integrating other systems like telematics and fuel cards into fleet management software allows you to further track driver productivity by getting a comprehensive view of their location, habits and spending.

Reports on drivers are then compiled into reports on durations, mileages and utilization to manage and improve driver assignments.

14. Technician Productivity

When thinking about repair costs, it’s important to understand the impact asset downtime can have on your budget. Technician productivity is crucial to getting vehicles back on the road and managing expenses.

Tracking work orders and maintenance through fleet management software ensures you remain aware of how long vehicles are in the shop and what work is being completed.

If you use a third party for maintenance, leveraging maintenance shop automations allows you to quickly approve or reject any service tasks, helping you control costs and manage productivity.

15. Performance Metrics

We’ve discussed a variety of fleet metrics, and while some have a granular scope, it’s important to compile these metrics to measure overall fleet performance.

When looking at reports in fleet management software, consider both real-time and historical data to spot trends and deficiencies in asset performance.

Tracking metrics on asset utilization, maintenance and fleet costs will help you pinpoint areas of improvement and determine future courses of action for the ultimate success of your fleet.

An integrated fleet management system like Fleetio helps you automatically track the fleet metrics that matter! Start your free trial or request a demo today.